- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

What Is Crimped Wire Mesh?

Crimped wire mesh is best defined as a woven wire variant in which the individual wires of the weave are pre-crimped prior to the weaving process. Pre-crimping involves bending the wires in consistent, uniform zig-zag patterns.

Additionally, crimped wires can be used to form various weave profiles, such as plain weaves, intermediate crimps, and flat-top crimps.

●Features of Crimped wire mesh

1.High strength, not easily deformed.

2.Wear resistance, corrosion resistance, and rust resistance.

3.High temperature is resistant.

4.High-quality ductility and toughness.

5.Mesh uniform.

6.Long service life.

7.The opening of the cloth is neat and precise.

8.Various materials for choice.

9.Beautiful surface.

10.Acid and alkali resistance.

●Characteristics of Material, Structure, and Craftsmanship

| aterial: | 1. stainless steel wire(304, 304L , 316 ,316L) 2. steel wire 3. galvanized steel wire. | |||

| Weaving | Pre-crimping before weaving | |||

| Wire diameter | 0.4-4mm(Customizable wire diameter) | |||

| Hole Size | 2mm-100mm or as your requested | |||

| Width | 0.4-2.5m | |||

| Length | 1-30m or as your requestd | |||

| Weaving Styles | Flat top, Intermediate, Interlock, Plain Weave(Four diagrams) | |||

①Flat top crimped wire

*Featuring a looser weave than the other types.

*Mesh Count: 1# - 4#, other sizes available

*Porosity: 56% - 94.1%

②Intermediate Crimped Wire

* With wires in every other crimp, the most common and most versatile type.

* Mesh Count: 1# - 4#, other sizes available

* Porosity: 56% - 94.1%

③Interlock Crimped Wire

* A very smooth, tight weave favored by architects.

* Mesh Count:1# - 4#, other sizes available

* Porosity: 56% - 94.1%

④Plain Crimped wire

* Also referred to as double crimped wire.

* Mesh Count: 1# - 4#, other sizes available

* Porosity: 56% - 94.1%

● Stainless Steel Crimped Wire Mesh

Features of Stainless Steel Crimped Wire Mesh: Specially woven, it provides a smooth, durable surface. Stable, impact-resistant, and wear-resistant, it's cost-effective and maintains a uniform mesh size over time.

● Galvanized Crimped Mesh

Features of Galvanized Crimped Mesh: woven with hot-dip galvanized or electroplated galvanized steel wire, with a surface zinc layer providing basic anti-corrosion protection, suitable for dry or mild corrosive environments. Corrosion resistance inferior to stainless steel, but more advantageous in cost sensitive projects

●Selection suggestions

1. Prioritize the scene of galvanized crimped mesh

◆Limited budget: Temporary building fences, agricultural breeding nets (such as pig farming nets)

◆Medium corrosive environment: mining screening and building reinforcement in dry areas

◆High temperature resistance requirement: It needs to withstand industrial filtration scenarios with a temperature of ≤ 133 ℃

2. It is necessary to choose stainless steel crimped wire mesh

◆Strong corrosive environment: chemical filtration, coastal facilities, food processing

◆High hygiene requirements: medical equipment, food machinery screening

◆Non magnetic requirement: Precision instrument perimeter protection (304/316 austenitic non-magnetic)

Note: The specific selection needs to be comprehensively evaluated based on the engineering project situation, temperature, medium pH value, mechanical load and other parameters

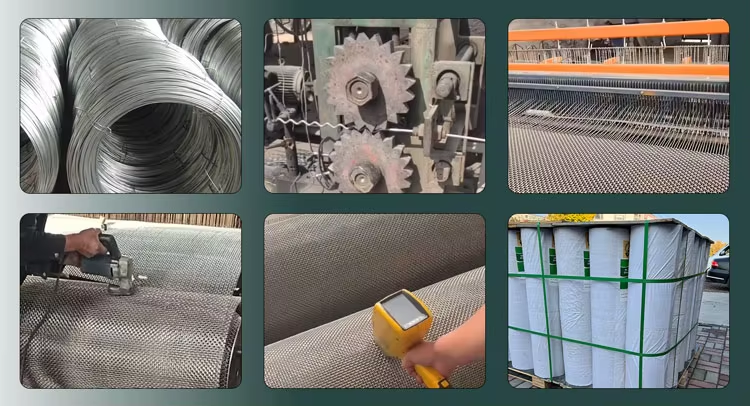

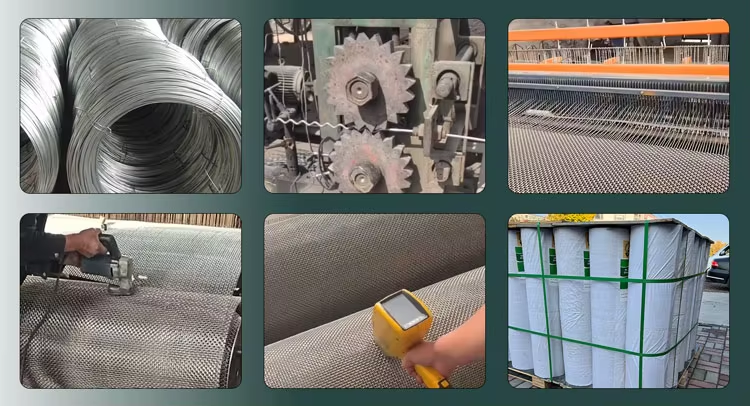

●Production Process:

●Application Scenarios Of Crimped Wire Mesh:

BBQ crimped wire mesh

Crimped wire mesh fence

Mining screen crimped mesh

●our certificate:

What Is Crimped Wire Mesh?

Crimped wire mesh is best defined as a woven wire variant in which the individual wires of the weave are pre-crimped prior to the weaving process. Pre-crimping involves bending the wires in consistent, uniform zig-zag patterns.

Additionally, crimped wires can be used to form various weave profiles, such as plain weaves, intermediate crimps, and flat-top crimps.

●Features of Crimped wire mesh

1.High strength, not easily deformed.

2.Wear resistance, corrosion resistance, and rust resistance.

3.High temperature is resistant.

4.High-quality ductility and toughness.

5.Mesh uniform.

6.Long service life.

7.The opening of the cloth is neat and precise.

8.Various materials for choice.

9.Beautiful surface.

10.Acid and alkali resistance.

●Characteristics of Material, Structure, and Craftsmanship

| aterial: | 1. stainless steel wire(304, 304L , 316 ,316L) 2. steel wire 3. galvanized steel wire. | |||

| Weaving | Pre-crimping before weaving | |||

| Wire diameter | 0.4-4mm(Customizable wire diameter) | |||

| Hole Size | 2mm-100mm or as your requested | |||

| Width | 0.4-2.5m | |||

| Length | 1-30m or as your requestd | |||

| Weaving Styles | Flat top, Intermediate, Interlock, Plain Weave(Four diagrams) | |||

①Flat top crimped wire

*Featuring a looser weave than the other types.

*Mesh Count: 1# - 4#, other sizes available

*Porosity: 56% - 94.1%

②Intermediate Crimped Wire

* With wires in every other crimp, the most common and most versatile type.

* Mesh Count: 1# - 4#, other sizes available

* Porosity: 56% - 94.1%

③Interlock Crimped Wire

* A very smooth, tight weave favored by architects.

* Mesh Count:1# - 4#, other sizes available

* Porosity: 56% - 94.1%

④Plain Crimped wire

* Also referred to as double crimped wire.

* Mesh Count: 1# - 4#, other sizes available

* Porosity: 56% - 94.1%

● Stainless Steel Crimped Wire Mesh

Features of Stainless Steel Crimped Wire Mesh: Specially woven, it provides a smooth, durable surface. Stable, impact-resistant, and wear-resistant, it's cost-effective and maintains a uniform mesh size over time.

● Galvanized Crimped Mesh

Features of Galvanized Crimped Mesh: woven with hot-dip galvanized or electroplated galvanized steel wire, with a surface zinc layer providing basic anti-corrosion protection, suitable for dry or mild corrosive environments. Corrosion resistance inferior to stainless steel, but more advantageous in cost sensitive projects

●Selection suggestions

1. Prioritize the scene of galvanized crimped mesh

◆Limited budget: Temporary building fences, agricultural breeding nets (such as pig farming nets)

◆Medium corrosive environment: mining screening and building reinforcement in dry areas

◆High temperature resistance requirement: It needs to withstand industrial filtration scenarios with a temperature of ≤ 133 ℃

2. It is necessary to choose stainless steel crimped wire mesh

◆Strong corrosive environment: chemical filtration, coastal facilities, food processing

◆High hygiene requirements: medical equipment, food machinery screening

◆Non magnetic requirement: Precision instrument perimeter protection (304/316 austenitic non-magnetic)

Note: The specific selection needs to be comprehensively evaluated based on the engineering project situation, temperature, medium pH value, mechanical load and other parameters

●Production Process:

●Application Scenarios Of Crimped Wire Mesh:

BBQ crimped wire mesh

Crimped wire mesh fence

Mining screen crimped mesh

●our certificate: