- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

Wedge wire is known as profile wire screen, V- wire screen, and wedge wire screen. It is created by wrapping a V- shaped profile wire cylindrical around longitudinal placed support rods. Each intersection of the profiles wire and support rod is well welded.

It has a smooth surface, resistant to clogging and a greater structural strength. Welded wedge wire screen is the most advanced product of modern technology used in many industries for screening, filtration, dewatering, drying and cleaning. The numerous combinations of profile wires and support rods, and the wide range of apertures between the wires and rods allows us to design some screen as your request.

The support grid is a flat screen panel that provides uniform flow collection which is essential in many applications. This is particularly important when screens are used to reserve expensive ion exchange resins. Support grids provide superior media retention characteristics in vessels of all types.

Material choice: SUS304, 304L, 321, 316L, 2205, 2507, 904L, Hastelloy,Titanium alloy and other special metal materials

Advantages:

Learn our sieve bends screens features and let your choose reasonably.

* Efficiently filtering, sizing and separating performance: no matter liquid or solids, sieve bends provide efficient separating to let the needed materials through while capturing the impurities, fibers and other unneeded materials out.

* Non-Clogging Screens: The V-shaped profile wires are less likely to clog than flat screens, which is important when dealing with materials that can be sticky or gooey.

* Continuous Operation: Due to their self-cleaning properties, wedge wire screens can operate continuously without

the need for frequent stoppages for maintenance.

* Durable: Stainless steel material make sieve bends can be used in harsh environments (high corrosive, high abrasive, high high viscosity) and works for a long service time.

For more information, please Contact us!!

Application:

①Smoke Exhaust Filter Wedge Screen:

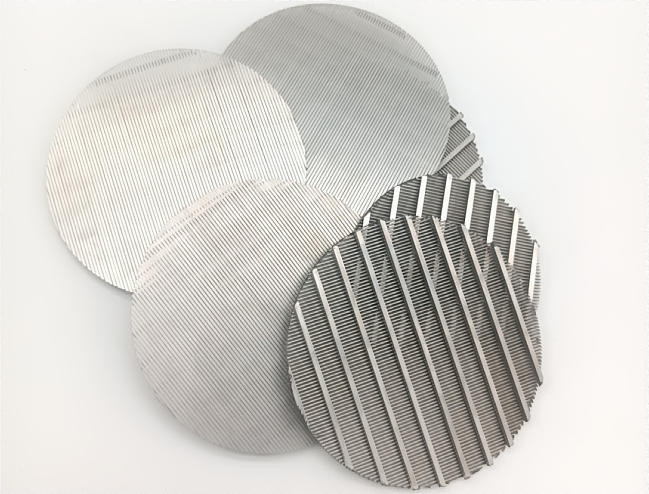

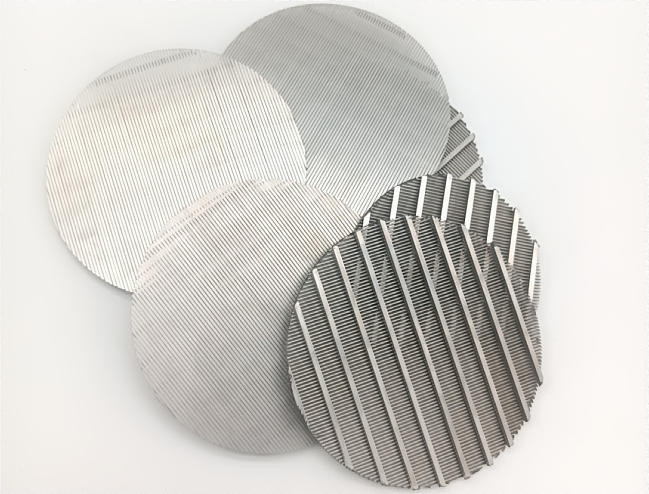

②Circular Wedge-shaped sieve mesh:

Wedge wire is known as profile wire screen, V- wire screen, and wedge wire screen. It is created by wrapping a V- shaped profile wire cylindrical around longitudinal placed support rods. Each intersection of the profiles wire and support rod is well welded.

It has a smooth surface, resistant to clogging and a greater structural strength. Welded wedge wire screen is the most advanced product of modern technology used in many industries for screening, filtration, dewatering, drying and cleaning. The numerous combinations of profile wires and support rods, and the wide range of apertures between the wires and rods allows us to design some screen as your request.

The support grid is a flat screen panel that provides uniform flow collection which is essential in many applications. This is particularly important when screens are used to reserve expensive ion exchange resins. Support grids provide superior media retention characteristics in vessels of all types.

Material choice: SUS304, 304L, 321, 316L, 2205, 2507, 904L, Hastelloy,Titanium alloy and other special metal materials

Advantages:

Learn our sieve bends screens features and let your choose reasonably.

* Efficiently filtering, sizing and separating performance: no matter liquid or solids, sieve bends provide efficient separating to let the needed materials through while capturing the impurities, fibers and other unneeded materials out.

* Non-Clogging Screens: The V-shaped profile wires are less likely to clog than flat screens, which is important when dealing with materials that can be sticky or gooey.

* Continuous Operation: Due to their self-cleaning properties, wedge wire screens can operate continuously without

the need for frequent stoppages for maintenance.

* Durable: Stainless steel material make sieve bends can be used in harsh environments (high corrosive, high abrasive, high high viscosity) and works for a long service time.

For more information, please Contact us!!

Application:

①Smoke Exhaust Filter Wedge Screen:

②Circular Wedge-shaped sieve mesh: