- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

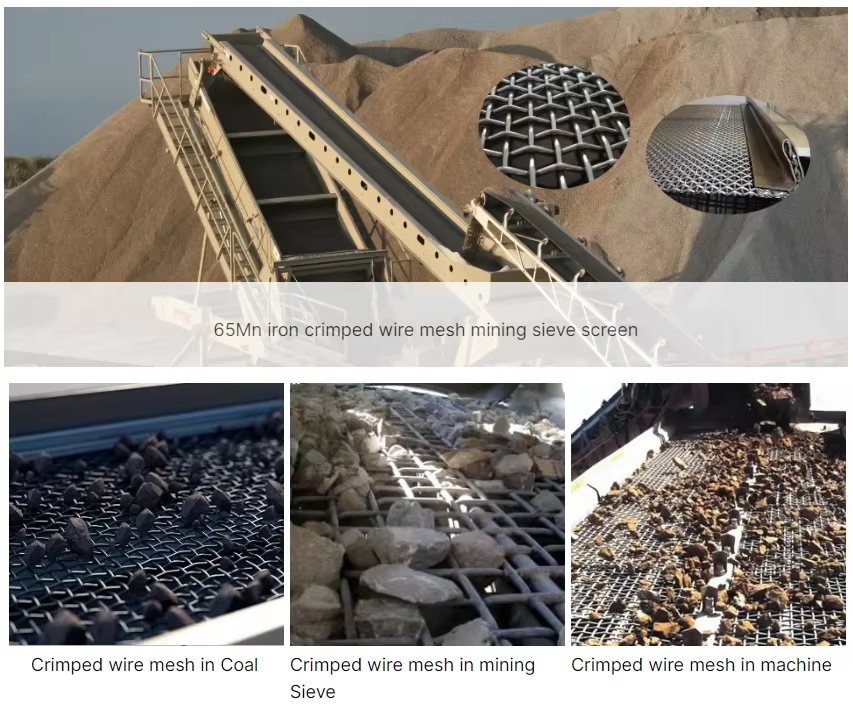

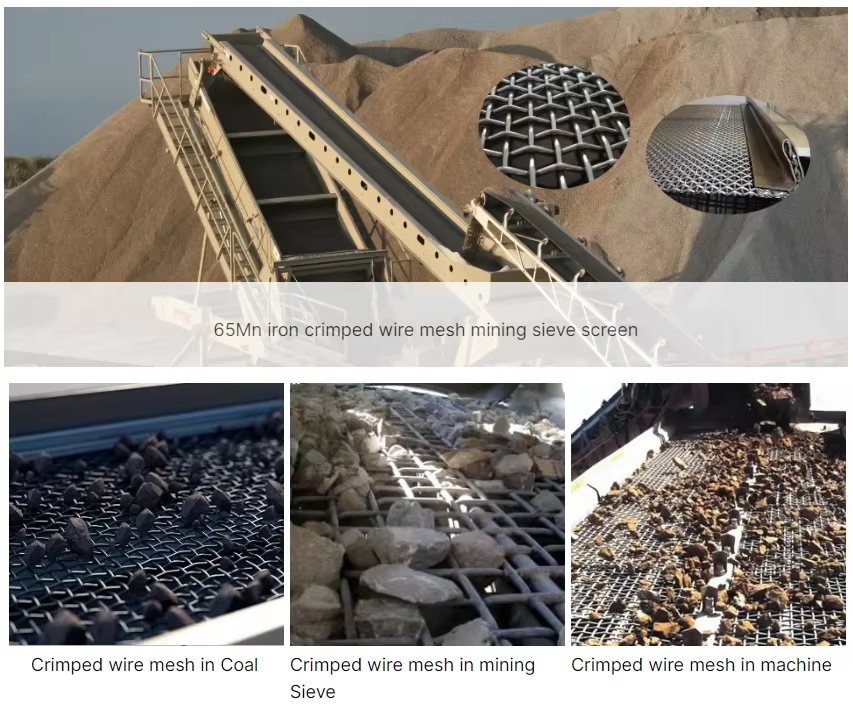

★Wear-Resistant and Impact-Resistant for Extended Service Life

The metal wires undergo cold drawing strengthening treatment (hardness can reach HV180 - 220), with a surface roughness controlled at Ra≤1.6μm, minimizing wire diameter loss caused by material friction. In coal screening tests, under the same working conditions, the wear life of the crimped wire mesh is 20% longer than that of ordinary woven meshes. Additionally, the wave-shaped node design disperses impact force. For example, in building exterior wall protection, it can effectively cushion the impact energy of falling objects (such as a 500g object dropping from a height of 2 meters), reducing the risk of mesh surface damage.

★Uniform and Precise Mesh Holes for Diverse Screening Needs

The weaving pitch of metal wires is controlled by high-precision molds, ensuring that the mesh hole uniformity error is ≤2% (for instance, on a mesh with a 5mm aperture, the actual measurement range is 4.9 - 5.1mm), which guarantees precise material screening.We support customization of various hole shapes, including square, rectangular.The mesh count ranges from 1/2 mesh to 100 mesh (corresponding to wire diameters of 0.2mm - 6.0mm).

Shown here are the most common wire diameters and sizes of crimped mesh design.

| Inch Mesh | Wire Diameter (inches) | Wire Diameter (mm) | Open Area (%) | Weight (Lbs/sq.ft.) | Weight (Kg/m²) |

|---|---|---|---|---|---|

| 1 | 0.120 | 3.048 | 77.44 | 0.929 | 4.536 |

| 1 | 0.135 | 3.429 | 74.82 | 1.178 | 5.752 |

| 1 | 0.187 | 4.750 | 66.10 | 2.278 | 11.122 |

| 1 | 0.250 | 6.350 | 56.25 | 4.124 | 20.135 |

| 1.5 | 0.120 | 3.048 | 84.64 | 0.781 | 3.813 |

| 1.5 | 0.135 | 3.429 | 82.81 | 1.178 | 5.752 |

| 1.5 | 0.187 | 4.750 | 76.62 | 2.278 | 11.122 |

| 1.5 | 0.250 | 6.350 | 69.44 | 4.124 | 20.135 |

| 2 | 0.120 | 3.048 | 88.36 | 0.462 | 2.256 |

| 2 | 0.135 | 3.429 | 86.96 | 0.585 | 2.856 |

| 2 | 0.187 | 4.750 | 82.17 | 1.125 | 5.493 |

| 2 | 0.25 | 6.350 | 76.56 | 2.016 | 9.843 |

| 3 | 0.120 | 3.048 | 92.16 | 0.308 | 1.504 |

| 3 | 0.135 | 3.429 | 91.20 | 0.390 | 1.904 |

| 3 | 0.187 | 4.750 | 87.92 | 0.748 | 3.652 |

| 3 | 0.243 | 6.172 | 84.46 | 1.264 | 6.171 |

| 4 | 0.12 | 3.048 | 94.09 | 0.231 | 1.128 |

| 4 | 0.135 | 3.429 | 93.36 | 0.292 | 1.426 |

| 4 | 0.187 | 4.750 | 90.87 | 0.561 | 2.739 |

| 4 | 0.25 | 6.350 | 87.89 | 1.003 | 4.897 |

For example, a 10-mesh crimped wire mesh (wire diameter 1.0mm, aperture 2.5mm) is commonly used for impurity screening in grain processing, while a 50-mesh fine-hole mesh (wire diameter 0.3mm, aperture 0.2mm) is suitable for the fine filtration of chemical powders, meeting the full range of screening requirements from coarse to precise.

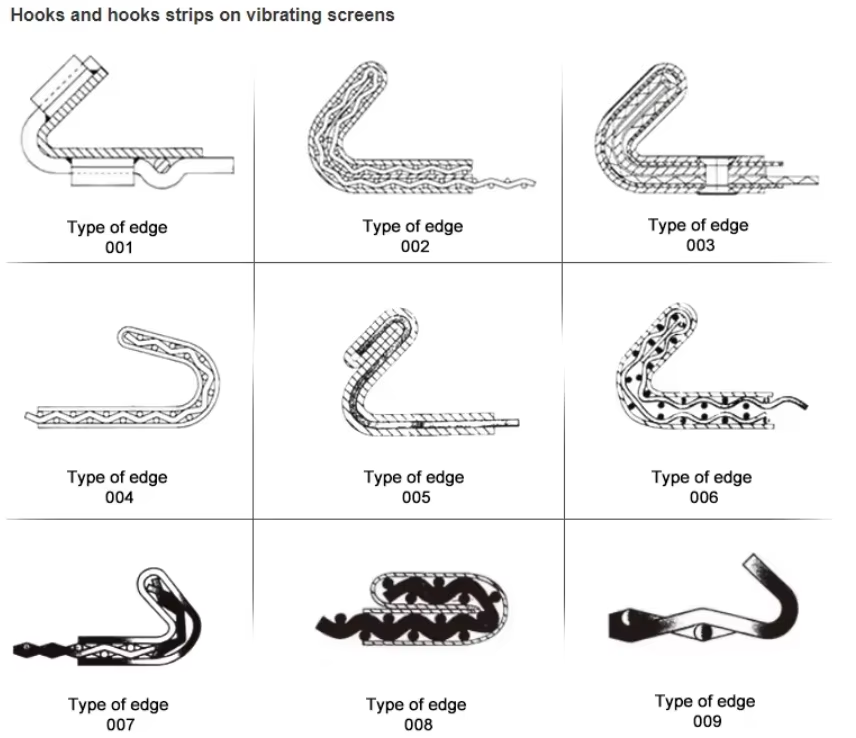

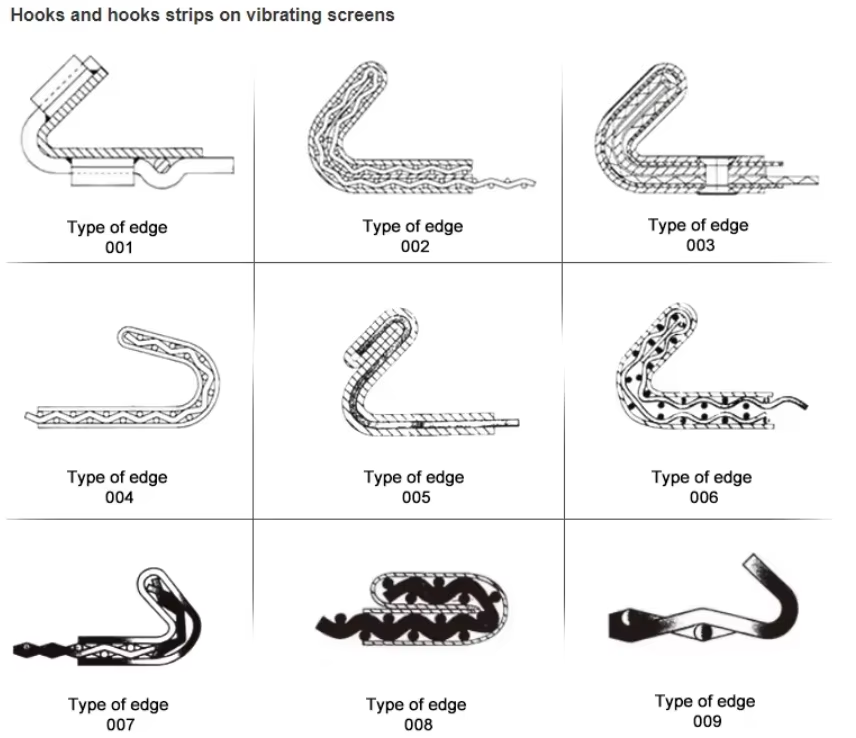

Flexible and Easy to Cut for Convenient Installation

The mesh rolls are highly flexible (with a bending radius ≤30cm when the wire diameter ≤2.0mm) and can be easily cut with ordinary scissors or wire cutters, adapting to irregular construction scenarios. Multiple installation methods are supported:

* Clip Fixing: Used for fence nets, it enables the installation of 10㎡ in just 30 minutes, saving 50% of the installation time compared to welded meshes.

* Bolt Assembly: Suitable for large-scale screening equipment. Pre-punched holes (with a diameter of φ6 - φ12mm) on the mesh edges allow for quick fixation with gaskets.

* Adhesive Bonding/Tie-Wrap Binding: Ideal for lightweight protection applications (such as window screens and greenhouse insect nets), requiring no professional tools for installation.

Material Selection for Sieve Mesh: Core Properties and Applications

| Material Category | Typical Grades | Core Composition (Main Elements & Content Range) | Core Characteristics | Application Scenarios |

|---|---|---|---|---|

| Stainless Steel (Most Common) | 304, 316, 316L, 310S, 430 | - 304: Fe ≈ 67%, Cr 18–20%, Ni 8–10.5% - 316: Based on 304, with additional Mo 2–3% - 310S: Cr 24–26%, Ni 19–22% | High corrosion resistance (resists acid, alkali, and humid environments); wear-resistant; good heat resistance (304: ≤800°C) Low cost; easy to process (cutting, welding, etc.) | Screening in food, chemical, and pharmaceutical industries |

| Low-Carbon Steel (Q235/A3 Steel) | Q235 (A3 Steel) | Fe ≈ 98%, C 0.12–0.20%, Mn 0.3–0.65%, Si ≤ 0.3% | Low cost; easy to process (cutting, welding, etc.) Poor corrosion resistance – surface treatment (galvanizing or powder coating) required | Coarse screening in mining and construction industries |

| High-Manganese Steel | Mn13, 65Mn | - Mn13: Fe ≈ 85%, Mn 11–14%, C 0.9–1.2% - 65Mn: Mn 0.6–0.9%, C 0.62–0.70% | Ultra-high wear resistance (surface hardens rapidly under impact load); strong tear resistance; good ductility | High-wear scenarios in mining and metallurgy industries (e.g., iron ore screening) |

| Brass/Bronze | Brass (H62, H65), Bronze (Tin Bronze) | - Brass (H62/H65): Cu 62–65%, Zn 35–38% - Bronze: Cu 80–90%, Sn 5–14% | Non-magnetic; excellent wear resistance; good corrosion resistance (especially resistant to weakly corrosive environments) | Precision screening and special environments such as explosion-proof scenarios |

★Rigorous Quality Control with Transparent Inspection Data

Each roll of our product undergoes three inspection processes before leaving the factory:

* Aperture Measurement: Sampling inspection (sampling rate ≥5%) is conducted using a laser diameter measuring instrument to ensure that the aperture deviation is within ±3%.

* Tensile Test: A 10cm×10cm mesh sample is randomly selected and subjected to a specified tensile force (e.g., ≥400N for 304 stainless steel mesh), ensuring that the nodes do not break.

* Salt Spray Test: Samples from each batch are tested for 48 - 1000 hours of salt spray exposure, and the corrosion grade is recorded (meeting the GB/T 6461-2020 standard, with a grade of ≥8 considered qualified). Inspection reports are available for download, and third-party inspection is supported, providing buyers with complete peace of mind..

★Wear-Resistant and Impact-Resistant for Extended Service Life

The metal wires undergo cold drawing strengthening treatment (hardness can reach HV180 - 220), with a surface roughness controlled at Ra≤1.6μm, minimizing wire diameter loss caused by material friction. In coal screening tests, under the same working conditions, the wear life of the crimped wire mesh is 20% longer than that of ordinary woven meshes. Additionally, the wave-shaped node design disperses impact force. For example, in building exterior wall protection, it can effectively cushion the impact energy of falling objects (such as a 500g object dropping from a height of 2 meters), reducing the risk of mesh surface damage.

★Uniform and Precise Mesh Holes for Diverse Screening Needs

The weaving pitch of metal wires is controlled by high-precision molds, ensuring that the mesh hole uniformity error is ≤2% (for instance, on a mesh with a 5mm aperture, the actual measurement range is 4.9 - 5.1mm), which guarantees precise material screening.We support customization of various hole shapes, including square, rectangular.The mesh count ranges from 1/2 mesh to 100 mesh (corresponding to wire diameters of 0.2mm - 6.0mm).

Shown here are the most common wire diameters and sizes of crimped mesh design.

| Inch Mesh | Wire Diameter (inches) | Wire Diameter (mm) | Open Area (%) | Weight (Lbs/sq.ft.) | Weight (Kg/m²) |

|---|---|---|---|---|---|

| 1 | 0.120 | 3.048 | 77.44 | 0.929 | 4.536 |

| 1 | 0.135 | 3.429 | 74.82 | 1.178 | 5.752 |

| 1 | 0.187 | 4.750 | 66.10 | 2.278 | 11.122 |

| 1 | 0.250 | 6.350 | 56.25 | 4.124 | 20.135 |

| 1.5 | 0.120 | 3.048 | 84.64 | 0.781 | 3.813 |

| 1.5 | 0.135 | 3.429 | 82.81 | 1.178 | 5.752 |

| 1.5 | 0.187 | 4.750 | 76.62 | 2.278 | 11.122 |

| 1.5 | 0.250 | 6.350 | 69.44 | 4.124 | 20.135 |

| 2 | 0.120 | 3.048 | 88.36 | 0.462 | 2.256 |

| 2 | 0.135 | 3.429 | 86.96 | 0.585 | 2.856 |

| 2 | 0.187 | 4.750 | 82.17 | 1.125 | 5.493 |

| 2 | 0.25 | 6.350 | 76.56 | 2.016 | 9.843 |

| 3 | 0.120 | 3.048 | 92.16 | 0.308 | 1.504 |

| 3 | 0.135 | 3.429 | 91.20 | 0.390 | 1.904 |

| 3 | 0.187 | 4.750 | 87.92 | 0.748 | 3.652 |

| 3 | 0.243 | 6.172 | 84.46 | 1.264 | 6.171 |

| 4 | 0.12 | 3.048 | 94.09 | 0.231 | 1.128 |

| 4 | 0.135 | 3.429 | 93.36 | 0.292 | 1.426 |

| 4 | 0.187 | 4.750 | 90.87 | 0.561 | 2.739 |

| 4 | 0.25 | 6.350 | 87.89 | 1.003 | 4.897 |

For example, a 10-mesh crimped wire mesh (wire diameter 1.0mm, aperture 2.5mm) is commonly used for impurity screening in grain processing, while a 50-mesh fine-hole mesh (wire diameter 0.3mm, aperture 0.2mm) is suitable for the fine filtration of chemical powders, meeting the full range of screening requirements from coarse to precise.

Flexible and Easy to Cut for Convenient Installation

The mesh rolls are highly flexible (with a bending radius ≤30cm when the wire diameter ≤2.0mm) and can be easily cut with ordinary scissors or wire cutters, adapting to irregular construction scenarios. Multiple installation methods are supported:

* Clip Fixing: Used for fence nets, it enables the installation of 10㎡ in just 30 minutes, saving 50% of the installation time compared to welded meshes.

* Bolt Assembly: Suitable for large-scale screening equipment. Pre-punched holes (with a diameter of φ6 - φ12mm) on the mesh edges allow for quick fixation with gaskets.

* Adhesive Bonding/Tie-Wrap Binding: Ideal for lightweight protection applications (such as window screens and greenhouse insect nets), requiring no professional tools for installation.

Material Selection for Sieve Mesh: Core Properties and Applications

| Material Category | Typical Grades | Core Composition (Main Elements & Content Range) | Core Characteristics | Application Scenarios |

|---|---|---|---|---|

| Stainless Steel (Most Common) | 304, 316, 316L, 310S, 430 | - 304: Fe ≈ 67%, Cr 18–20%, Ni 8–10.5% - 316: Based on 304, with additional Mo 2–3% - 310S: Cr 24–26%, Ni 19–22% | High corrosion resistance (resists acid, alkali, and humid environments); wear-resistant; good heat resistance (304: ≤800°C) Low cost; easy to process (cutting, welding, etc.) | Screening in food, chemical, and pharmaceutical industries |

| Low-Carbon Steel (Q235/A3 Steel) | Q235 (A3 Steel) | Fe ≈ 98%, C 0.12–0.20%, Mn 0.3–0.65%, Si ≤ 0.3% | Low cost; easy to process (cutting, welding, etc.) Poor corrosion resistance – surface treatment (galvanizing or powder coating) required | Coarse screening in mining and construction industries |

| High-Manganese Steel | Mn13, 65Mn | - Mn13: Fe ≈ 85%, Mn 11–14%, C 0.9–1.2% - 65Mn: Mn 0.6–0.9%, C 0.62–0.70% | Ultra-high wear resistance (surface hardens rapidly under impact load); strong tear resistance; good ductility | High-wear scenarios in mining and metallurgy industries (e.g., iron ore screening) |

| Brass/Bronze | Brass (H62, H65), Bronze (Tin Bronze) | - Brass (H62/H65): Cu 62–65%, Zn 35–38% - Bronze: Cu 80–90%, Sn 5–14% | Non-magnetic; excellent wear resistance; good corrosion resistance (especially resistant to weakly corrosive environments) | Precision screening and special environments such as explosion-proof scenarios |

★Rigorous Quality Control with Transparent Inspection Data

Each roll of our product undergoes three inspection processes before leaving the factory:

* Aperture Measurement: Sampling inspection (sampling rate ≥5%) is conducted using a laser diameter measuring instrument to ensure that the aperture deviation is within ±3%.

* Tensile Test: A 10cm×10cm mesh sample is randomly selected and subjected to a specified tensile force (e.g., ≥400N for 304 stainless steel mesh), ensuring that the nodes do not break.

* Salt Spray Test: Samples from each batch are tested for 48 - 1000 hours of salt spray exposure, and the corrosion grade is recorded (meeting the GB/T 6461-2020 standard, with a grade of ≥8 considered qualified). Inspection reports are available for download, and third-party inspection is supported, providing buyers with complete peace of mind..

content is empty!